The ultimate goal of a digital thread strategy is to provide access to traditionally difficult to share technical and knowledge-based data. However, because it is a strategy or framework, not a discrete deliverable or product, it is imperative to identify a platform that meets your specific digital thread needs. The following 5 technical requirements offer a direct path, or blueprint, to success based on the experience of many companies that have improved their operations from engineering to manufacturing, across the supply chain, and out through service and support.

“A digital thread is a framework that enables the collection, organization and presentation of data for multiple factors that influence a product or process and their evolutions over their respective life cycles. This integration and organization of data and information allow multiple users to access, integrate, organize, trace and transform disparate technical and knowledge-based data from multiple operational and enterprise-level systems.” -Gartner®, "Hype Cycle™ for Manufacturing Digital Optimization and Modernization, 2021, Christian Hestermann, et al, 23 July 2021. GARTNER and HYPE CYCLE are a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally and are used herein with permission

IP Security is Imperative

Without improvements in security, sharing intellectual property across the supply chain offers more risks than rewards. File-less web content is the key to secure data sharing. Files, by design, are meant to be transferred, including person to person. Once transferred, they can be taken out of a secure network. Traceability often disappears. To combat this, companies are investing in technologies to provide secure, traceable content access to their supply chain without providing the files. This file-less web content approach provides the information but does not require the file transfer. By providing web content only, you can better maintain the security of the information. There are no files to be sent, leaked, or otherwise removed from view. User interactions are monitored and tracked. Access is actively managed and time-limited. Data is redacted as it is processed for file-less consumption. And session-aware dynamic watermarking is applied to content being viewed, deterring collaborators from screenshots and other IP security workarounds. Learn more about security requirements and common questions in our eBook: Addressing IP Security and Digital Rights Management (DRM) in the Supply Chain.

Human Readable Data

Machine readable data has been great for system integration, and business process optimization, but has left out the people, presenting communication and collaboration challenges. It is nearly impossible for most people to understand detailed bill of material (BOM) information or complex product manufacturing information (PMI) without assistance from the expert(s) responsible for the data and knowledge.

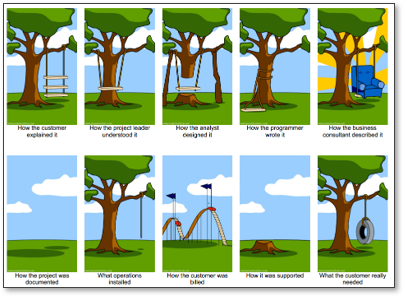

Human readable data is crucial to optimizing digital thread value, enabling teams to communicate clearly, source the right parts, understand the work that needs to be done, and avoid the age-old tire-swing miscommunication scenario. Engineering error rates drop significantly when information is presented in a way that everyone can consume it. Learn how a company reduced engineering error rates by 40% by connecting people across their supply chain to their digital thread.

Modularity and Standards

Because the digital thread is a framework, it’s important that your solution be built on platform with a modular design that supports a variety of standards, preferably open standards. This allows a digital thread platform to become your digital thread, mapping to your systems, your processes, and your people.

From a solution sustainability standpoint, and lifetime value, modularity enforces structure for human and machine interpreted information but also offers a flexible architecture that can be easily updated to stay current, avoiding technology/solution obsolescence.

Standards provide interoperability to account for a constantly changing and diverse supply chain IT landscape. Different tools and systems produce a variety of formatted data. Standards allow for file-less content to be seamlessly updated throughout the lifespan of the information. And open standards take it one step further preventing vendor lock-in.

Contextualized Collaboration

Discussing technical data without the technical data is hard, sometimes impossible. Yet that’s the most common scenario. One tool manages the data, and another tool manages the collaboration. Electronic documents, email, and instant messages have become the standard for communicating the majority of information in the world, but generally remain disconnected from the digital thread. These forms of communication typically rely on siloed systems or individuals to track and manage themselves and have little or no context of the data being discussed.

Contextualized collaboration brings the data together with these familiar communication and markup tools to minimize miscommunication and capture a traceable history of communication that is often lost in a disconnected process.

Mobile First Access

People and teams should not be limited by the type of device they are using. To maximize the value of a digital thread strategy, every person needs to be able to securely access information from a variety of devices.

This is not to say that every person across the supply chain will access data on a mobile device, but true accessibility needs to be device agnostic. And a mobile-first strategy ensures that a consistent user experience will be provided across any type of device, improving user adoption.

Final Thoughts

For manufacturers considering digital thread strategies, it important to understand the technical requirements that result in business value. Anark has taken a security focused, people-centric approach to technical data sharing and collaboration by sourcing information from all the right systems, assembling them into template-based technical data packages in the cloud, and making them securely accessible on any device. This ensures everyone has access to the digital thread data that they need and access to each other through contextualized collaboration; yielding faster iterations, reduced material waste, and higher-quality products and services with substantial cost savings

Learn more about the benefits of supplier collaboration.