In case you missed it, Digital Engineering recently released the results of its annual Technology Outlook survey. There were a few big stories to come up this year. One of the most notable (and least surprising) was the clear emergence of AI as the technology everyone’s watching. That said, additive manufacturing isn’t going anywhere, although its momentum has slowed. Elsewhere, the survey cited some persistent challenges in both collaboration and in developing and nurturing a digital thread – trends that could prove problematic later on.

It’s always interesting diving into these insights at the start of the year and getting a glimpse of what the next few months might bring. But since this year’s survey overlaps with so much of our work here at Anark, we thought we’d not only share these findings with you, but offer up a few of our own thoughts as well. After all, when it comes to cutting-edge technology and improving collaboration and alignment across your product lifecycle, we know a thing or two.

So let’s dive in and take a look at what the future of engineering holds.

The Challenge of Collaboration in Engineering Teams

While the challenge of collaboration within engineering actually dropped a place between this year and last, it only moved from first place to second, further highlighting its persistence. In order to understand what’s going on beneath the surface here, it may be helpful to look at another survey we’ve highlighted before. Peering into the state of technical collaboration, Lifecycle Insights found that 50 percent of engineering time is thrown away at tasks like finding data, packaging it up and sharing it with stakeholders, and then explaining it.

The takeaway here is that, despite investments in systems like ERP and PLM, there remains a wide disconnect between the data that gets shared and the way that people prefer to ingest it. This means, in order for communication and collaboration to happen, engineers find themselves putting in a lot of time and effort that probably would have been better spent elsewhere.

Of course, this is exactly the reason we developed Anark software. Requiring coworkers and other collaborators to wade through cumbersome PLM systems and product configurations or figure out interoperability issues is no way to build an efficient workplace. Instead, our desktop and cloud solutions, Anark Workstation and Anark Collaborate, as well as our publishing engine, Anark Publish, are all designed to streamline the process of finding, packaging, sharing, and collaborating on your technical data. The impact of this can help spur innovations across your digital thread, from your manufacturing space through your suppliers and all the way to your customers.

Additive Manufacturing as a Revolution in Design Engineering

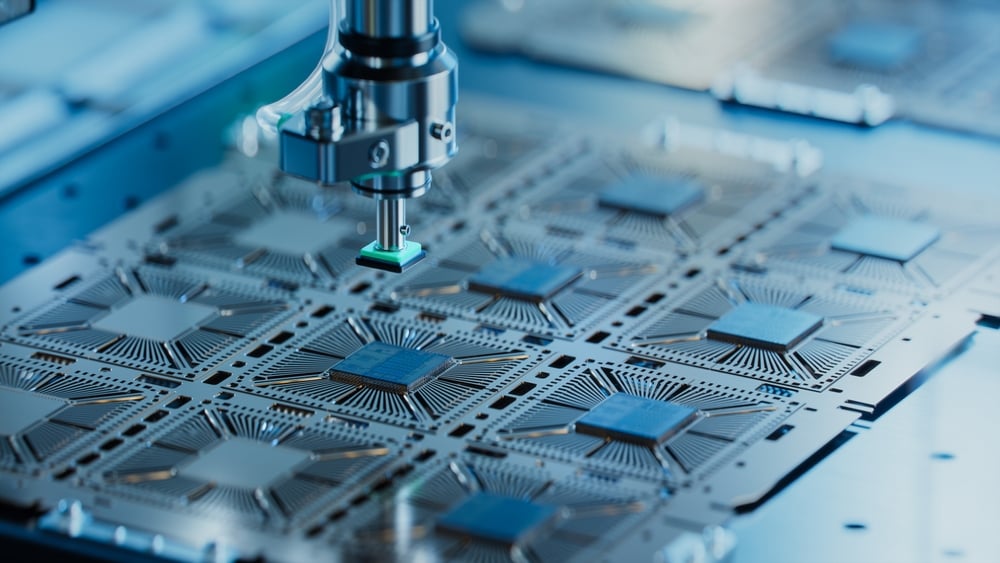

As has been the case in previous years, a majority (54 percent) of the engineers surveyed agreed that additive manufacturing (AM) will upend the design engineering process. Already, 86 percent said they were using 3D printing to prototype their designs, while 55 percent are also putting it to use in testing. Although these represented slight drops as compared to the previous year, they are nevertheless clear evidence of additive manufacturing’s ongoing promise.

This doesn’t come as a huge surprise. As compared with traditional manufacturing, AM makes it possible to produce parts with much more complex geometries, combine multiple part assemblies into single monolithic parts, streamline and simplify mass customization, and more. Perhaps most significantly, the ability to rapidly turn out new designs and iterations with AM has made it an ideal tool for part development and prototyping.

So why hasn’t its popularity continued to increase, rather than stagnate, year over year? We can think of at least one plausible reason. Despite its advantages, AM is still not yet a seamless manufacturing process like machining, casting, and other subtractive manufacturing processes. Instead, it requires significant collaboration between the designers and manufacturers in order to ensure all material specifications and performance requirements are met. Any miscommunications or inefficiencies (like the ones described in the section above) can slow down this process – or even grind it to a halt.

This is why it makes little sense for manufacturers to take their collaborative process outside of its appropriate context. With Anark Workstation, you can share and distribute 3D PDFs across your suppliers, partners, and customers, while also getting support for important data types like 2D drawings, technical data packages (TDP), STEP, and more. This allows you to streamline the production process, shorten cycle times, and capture critical operational knowledge for future re-use.

AI and Machine Learning in Product Design and Development

As it has throughout nearly every other industry out there, AI and machine learning (ML) continue to make a splash in the product design and development world. This year, an impressive 65 percent of respondents named it as the most important technology to watch, giving it enough of a boost to surpass additive manufacturing for the first time. While engineers are still likely testing out the best use cases for this technology, it’s already become an efficient way for them to explore new designs and perform rapid simulations and analysis.

As it has throughout nearly every other industry out there, AI and machine learning (ML) continue to make a splash in the product design and development world. This year, an impressive 65 percent of respondents named it as the most important technology to watch, giving it enough of a boost to surpass additive manufacturing for the first time. While engineers are still likely testing out the best use cases for this technology, it’s already become an efficient way for them to explore new designs and perform rapid simulations and analysis.

In other words, AI/ML have become great tools for introducing new levels of automation into the manufacturing process – although you’ll be more likely to hear this described as “digital assistance.” For instance, when applied to manufacturing analysis, AI can be programmed to automatically look for potential flaws or weaknesses, then suggest possible improvements. It could also be used to generate new technical drawings, compare designs against each other, and make recommendations. This can help free up time for designers to focus on more creative or strategic tasks.

Overcoming Challenges with the Digital Thread

Within the context of the manufacturing industry, the digital thread can probably still be called a fairly new concept. In short, it refers to an entire ecosystem across the product lifecycle that encompasses both the physical and digital worlds. Within this closed loop, data is unified and organized at every stage, from design and production to distribution and sales, helping to improve efficiency, streamline communication, and increase productivity, among many other benefits.

It’s a broad and ambitious concept, which may be why so few respondents claimed to be familiar with it – 32 percent said they didn’t know anything about it at all. Fortunately, the survey also looked at some of the challenges associated with implementing and maintaining a digital thread. By far, the most prominent was the sheer complexity of designing and developing such a system. People just don’t know where to start. Following closely behind was the related issue of integrating existing ERP, PLM, and other systems. Security issues were also prominent, as was the challenge of getting management buy-in.

These are all valid concerns any organization will have to confront if they want to get serious with the digital thread. They’re also all issues Anark has been designed to deal with. Consider what you can do with our collaboration hub. By connecting all of your engineering, manufacturing, procurement, suppliers, and other entities together within the Anark Collaborate platform, you can provide open but secure access to all your technical data without the need or complexity of separate data management systems and file-sharing services. And with our PLM integrations and CAD adapters, you’ll be able to publish and deliver the data packages to whoever needs them.

Moving Forward With The Right Partner

If there’s any big lesson to learn from Digital Engineering’s survey, it’s that the next year holds some exciting new developments in the field, along with a host of older and more familiar challenges. While AI and additive manufacturing are both poised to change the profession, their main impediment will be continuing difficulties in successfully collaborating and communicating across the product lifecycle.

But the very fact these difficulties continue to persist should be evidence that the traditional ways of working – siloed information systems, inefficient communication streams, complex processes for sharing data – aren’t sustainable long-term. Instead, in order to leverage the technological advancements transforming engineering, organizations need to put into place better connected, cohesive, and collaborative tools – which is just what Anark is designed to do.

So if any of the engineering challenges discussed above resonated with you, take the time to explore how our solutions can help you this year, or reach out directly and connect with us. Let’s transform your teams together.

FAQs

Why does collaboration continue to be such a challenge within engineering?

In short, because it’s still too hard to share technical data and communicate across the product lifecycle. While PLM and ERP systems may be great for a small subset of power users, the majority of people would rather communicate with the same tools they use elsewhere: email, messaging, chat applications, and so on. Otherwise, they’ll have to spend too much of their time finding the right information, properly packaging and sharing it to relevant parties, and explaining it to them.